Electroless Nickel

Sandblasting

Electroless Nickel is a chemically-performed coating material whose main characteristics are summarized as follows:

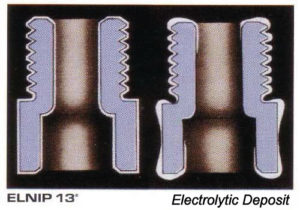

UNIFORMITY

- Excellent adherence

- Total protection for internal parts (slots, holes, etc.)

- Absence of “ridge” effects

- Absolute respect for basic texture

- Avoiding final mechanical processing (rectification)

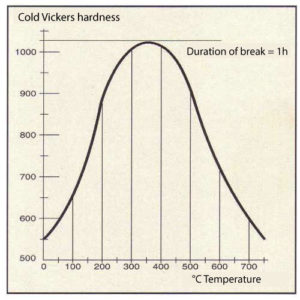

HARDNESS

High superficial hardness. Depending on the base material, by applying suitable heating treatments, it is possible to obtain values of hardness of a minimum of 500 Vickers (48 HCR) and a maximum of approx. 1000-1050 Vickers (70/72 HRC)

RESISTANCE

High resistance to corrosion and wear. The presence of phosphorus in the alloy composition lends the process characteristics of:

- Self-lubrication

- Water-repellency

Applicability to metals

- 1. Chemical Composition

- 2. Melting point

- 3. Specific weight

- 4. Expansion coefficient

- 5. Electrical resistance

- 6. Magnetic sensitivity

- 7. Elastic modulus

- 8. Hardness

- 9. Ductility

- 10. Resistance to abrasion

- 11. Coefficient of friction

- 12. Resistance to thermal changes

- 13. Adherence

- 14. Coating regularity

- 15. Weldability

- 16. Reflective power

Phosphorus: 10-13%

Hydrogen: 0.0016%

Nitrogen: 0,005%

Oxygen: 0.0023%

- Steel 12 × 10-6 cm / cm ° C

- Copper 17 × 10-6 cm / cm ° C

- Brass 19 × 10-6 cm / cm ° C

- Duralumin 23 × 10-6 cm / cm ° C

Un sottile strato di deposito, da 5 a 10 micron, è sufficente per saldare l’alluminio o l’acciaio inossidabile.

Nell’ultravioletto estremo ossia tra i 400 ed i 100 agstròm, il suo potere riflettente è del 50%.

Diagram of hardnesses

Table of porosity after 120 hours of exposition to salt mist.

| Thickness Μ | 10 | 25 | 50 | 75 |

| Chromium hard N. of pores | Very many | 250 | 16 | 8 |

| Chemical Nickel N. of pores | 30 | 6 | 1 | 0 |

Uniformity

Compared with traditional chromium plating treatments, it guarantees the possibility of obtaining a total and uniform covering on any geometry.

The non-toxicity

Tests with food substances have shown that the coating has given negative results as to nickel release, thus complying with American and European regulations. In fact, the particular conditions of use and maintenance of the plants (presence of corrosive and oxidizing substances, washing with sterilizing products) have considerably influenced the choice of the type of protection previously performed (cadmium, zinc, paint) towards the treatment. This solution has also allowed in some cases the replacement of “noble” materials, such as stainless steel and bronze, with others less valuable but featuring more suitable technical characteristics for the required use.

Working temperatures

As it can be observed in point 8 concerning hardness, it is necessary to reach higher temperatures only if a harder coating is wished. Some metals can be negatively affected by such temperatures; in order to avoid possible inconveniences, our technicians are available for any preventive consultation.

Protection and masking

There is no limitation as to protection and/or masking: holes, pins, internal and external diameters can all be protected. The only limitation is given by the high costs associated with such operations which require manpower; therefore, we kindly suggest to verify, together with our technicians, the real need to perform such operations.

Hardnesses of Base Metal

It is not necessary for a base metal to be hard to have maximum wear resistance. All that it shall do is to withstand operating loads without excessive bending. However, attention shall be paid to the choice of the metal hardness, whenever wear resistance derives from heavy shock loads, for which a thin coating might break should the base metal collapse. For this reason, the materials often undergo treatments such as stabilization, quenching, annealing, tempering, cementation, etc. It must be remembered that while treatments such as stabilization, annealing and tempering do not create any problem, the processes of quenching and cementation require a preliminary micro-sandblasting in order to guarantee good adherence. While carbonitriding may be critical, nitriding shall be excluded.

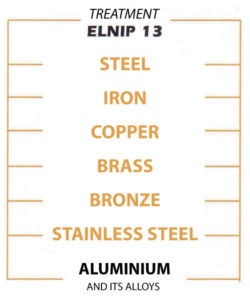

Applicability to metals

The coating may be applied to the following metals:

Sandblasting

Our company offers different kinds of sandblasting or shot blasting.

We offer fine sandblasting or micro sandblasting on metal parts that need superficial cleaning without affecting piece geometries or dimensions in the drawing.

Since micro-blasting is carried out using aluminum oxide, it is also suitable for stainless materials.

Shot blasting or shot peening is instead carried out for carpentry or semi-finished details using angular metal grit or garnet in case of stainless materials.

As far as micro-sandblasting is concerned, we are equipped with automatic and semi-automatic sandblasting machines for small dimensions and a semi-automatic sandblasting cabinet the size of 4 m3 while for shot blasting, we use a cabin of 8 m3 equipped with automatic rotating table with a capacity of 1000 kg.

For both processes it is possible to assemble localized protections to prevent the latter from being sandblasted or grit.